💎 How Piercing Jewelry Is Made

Share

Piercing jewelry may be small in size, but behind every piece lies a world of craftsmanship, precision, and design. Ever wondered how your favorite barbells, hoops, or studs are made? Let’s take a look behind the scenes.

1. Material Selection: The Foundation of Quality

Every piece of high-quality piercing jewelry begins with the right material. Popular choices include surgical-grade stainless steel, titanium, 14k or 18k gold, and biocompatible plastics like PTFE. These materials are hypoallergenic, corrosion-resistant, and safe for long-term wear — especially in healing piercings.

The choice of material impacts not only appearance but also comfort, safety, and longevity.

2. Precision Shaping: Forming the Basics

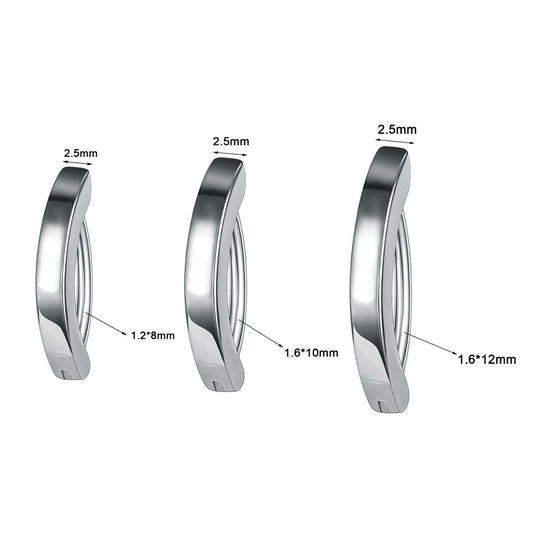

Once the material is chosen, the jewelry is cut and shaped. This step is often performed using high-precision CNC (Computer Numerical Control) machines or by skilled artisans. Whether it’s a straight barbell, curved bar, labret stud, captive bead ring, or clicker hoop — each piece must meet exact specifications for gauge, length, and fit.

This step lays the structural foundation for the final product.

3. Polishing: Smooth, Shine, and Safe

After shaping, each piece goes through an intensive polishing process. The goal is to eliminate sharp edges or surface imperfections and create a mirror-like finish.

Highly polished jewelry isn’t just about beauty — it also reduces irritation and speeds up healing by preventing bacteria from accumulating in scratches or rough surfaces.

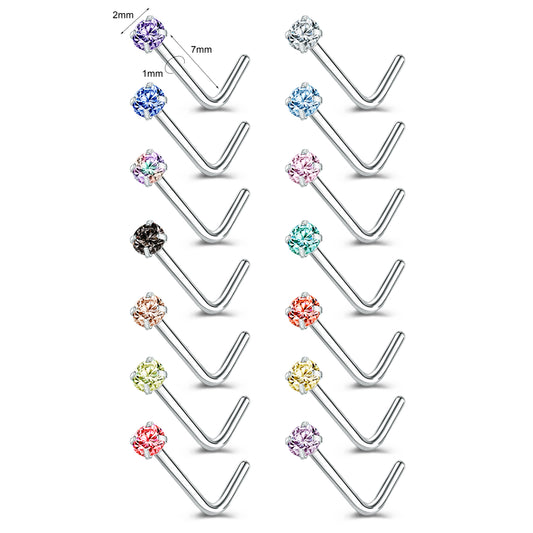

4. Gem Setting & Detail Work

For jewelry with stones or decorative features, this is where the sparkle happens. Each gem — whether a cubic zirconia, opal, or genuine gemstone — is carefully set by hand or machine. Good setting technique ensures the gem stays secure while aligning symmetrically with the design.

Charms, dangles, and engraving may also be added during this stage to create unique, eye-catching designs.

5. Sterilization & Quality Control

Before reaching the customer, each piece of jewelry undergoes rigorous quality checks. This includes measuring the size and threading, checking for polish quality, inspecting gem settings, and ensuring every surface is flawless.

For professional-grade jewelry, sterilization in an autoclave is often performed, ensuring the item is safe to use immediately in fresh piercings.

6. Packaging & Presentation

Finally, the jewelry is carefully packed — sometimes in sterile packaging, sometimes in branded boxes or pouches — and made ready for its new owner. High-quality packaging not only protects the product but also reflects the brand’s attention to detail.

Final Thoughts

Piercing jewelry isn’t just an accessory — it’s a tiny piece of art made with science, precision, and care. The next time you wear your favorite piece, remember: behind its beauty is a story of expert craftsmanship and dedication.